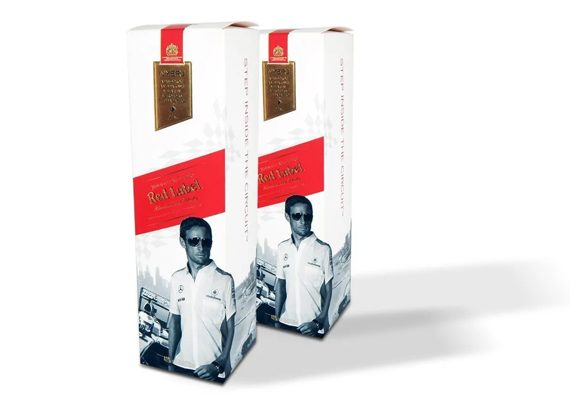

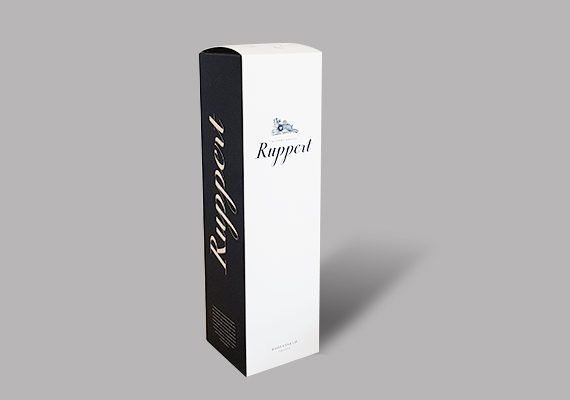

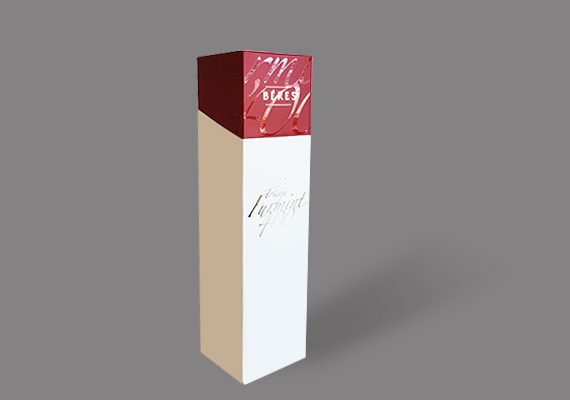

Custom designed bottle packaging

We are offering custom made packaging solutions for unique and high-end spirits, brandies, liqueurs, vodka, and whisky, to name a few. Whether it is the unique construction of the packaging, a special material or surface treatment – the options are practically endless, that can help you highlight the features of your product and enhance its prestige.

request an offerFurther information on the custom designed bottle packagings

- We are designing decorative packaging boxes for various kinds of spirits and brandies.

- We are offering professional consultancy even before the design phase: we can present you samples from previous productions with the possible options, materials, and surface treatments.

- We are producing packaging for bottles of all shapes and sizes. You can choose from traditional designs and systems with one-of-a-kind shapes or closures.

- The system of the box is laid out by our designers adjusted specifically for the given product. Before the start of the production we provide you with a dummy of the box so that you can check whether it would be fit for its purpose.

- Different materials are recommended depending on the needs. Scroll down for further information on the materials.

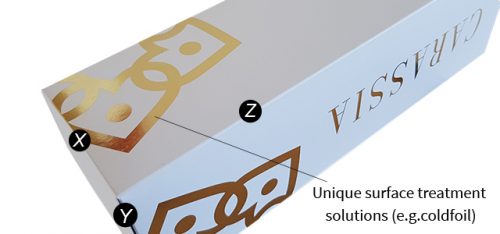

- To achieve the unique and customized look, you can choose from various surface treatment solutions (e.g. spot UV varnish, hot foil stamping, embossing etc.). See further details below.

- All parts of the manufacturing process are done in-house, that can significantly reduce the production lead time.

Legend:

x Width

y Depth

z Height

Legend:

x Width

y Depth

z Height

Materials

In this section you can read about the materials that are most often used for bottle packaging.

Standard cardboard

GC2 cardboard

Made of virgin fibre, built up in three layers and fully coated on the top side. The top side is double coated, the reverse side is slightly cream coloured. Thanks to its smooth surface and abrasion resistance, the quality of the print stays the same on it for a long time. Optimized for folding, laminating, spot UV varnishing and gluing.

Features optimal price-quality ratio, good quality and standard firmness in structure.

GC2: made of virgin fibre, built up in three layers and fully coated on the top side. The top side is double coated, the reverse side is slightly cream coloured.

Premium grade bright white cardboard

Crownboard Prestige

Very high quality bright white GC1 cardboard. Its top side is coated, the reverse side is uncoated, and made exclusively of virgin fibre. Offers quality printability and particularly suitable for the application of different surface treatments. Its structure is strong and sturdy. Particularly suitable for printing the application of different surface treatments. Firm cardboard material.

Strong and firm white cardboard

Printline 650g

Cardboard with sturdy and strong structure. Its caliper is between that of the greyboard and the GC2 cardboard. It is made of virgin fiber, the pulp does not contain recycled waste material. It consists of three layers, and its top side is machine coated.

Printline 650 gsm

Cardboard with sturdy and strong structure. Its caliper is between that of the greyboard and the GC2 cardboard. It is made of virgin fiber, the pulp does not contain recycled waste material. It consists of three layers, and its top side is machine coated. Offers quality printability and particularly suitable for the application of different surface treatments. Its middle layer is rigid, on the reverse side a white uncoated kraft layer is mounted. Standard quantity with very firm structure.

Mounted corrugated fiberboard

Mounted corrugated fiberboard

A liner sheet is mounted on the corrugated side of the corrugated fiberboard (a coated sheet of paper is adhered to the corrugated sheet). This makes the packaging strong and hard-wearing with a naturally elegant appeal.

Corrugated fiberboard: environmentally friendly and completely recyclable. It consists of a corrugated sheet and a smooth linerboard that is adhered to the corrugated sheet. This gives the material sturdy and strong properties. The printed sheet is then adhered (mounted) on the open side of the corrugated board, which serves as the third layer of the material.

Mountsheet (liner): unless otherwise required, it is generally a bright white coated paper, that is very well suited for printing and different surface treatment solutions.

Mounted corrugated fiberboard a liner sheet is mounted on the corrugated side of the corrugated fiberboard (a coated sheet of paper is adhered to the corrugated sheet). This makes the packaging strong and hard-wearing with a naturally elegant appeal. The beautiful white liner sheet printed with the artwork is mounted (adhered) to the corrugated side of the open corrugated board.

Rustic brown material + corrugated fiberboard

Rustic brown material + corrugated fiberboard

A 180 gsm CrownBoard Craft paper is mounted on an open corrugated board with Eflute (a coated sheet of paper with its brown side on the outside is adhered to the corrugated sheet). This makes the packaging strong and robust with a natural appeal.

CrownBoard Craft: strong cardboard that features a triple coated top and a brown reverse side, with high tearing resistance. It is recommended for products where the packaging needs to be solid and hard-wearing.

Corrugated fiberboard with E flute: environmentally friendly and completely recyclable. It consists of a corrugated sheet and a smooth linerboard that is adhered to the corrugated sheet. This gives the material sturdy and strong properties. The printed sheet is then adhered (mounted) on the open side of the corrugated board, which serves as the third layer of the material.

A 180 gsm CrownBoard Craft paper is mounted on an open corrugated board with Eflute (a coated sheet of paper with its brown side on the outside is adhered to the corrugated sheet). This makes the packaging strong and robust with a natural appeal.

Mounted greyboard

Mounted greyboard

Very strong and rigid material, recommended for exclusive, high-end packaging. The printed mountsheet (liner) is adhered (mounted) on the greyboard whose thickness can vary depending to the given needs.

Greyboard: environmentally friendly and recyclable board made exclusively of recycled paper waste material, with multiple layers glued together.

Mountsheet (liner): unless otherwise required, it is generally a bright white coated paper, that is very well suited for printing and different surface treatment solutions.

Very strong and rigid material, recommended for exclusive, high-end packaging. The printed mountsheet (liner) is adhered (mounted) on the greyboard whose thickness can vary depending to the given needs. Stern and rigid greyboard

Recommended surface treatments

You can find here further information – short descriptions and an introductory video – about the most common surface treatments used in case of bottle packagings.

Embossing

Embossing

The embossing offers clean and elegant look for the packaging. The technique is used generally on single colour or unprinted areas. During the process letters or design elements are embossed in the material with an embossing cliche. The higher the grammage of the paper, the more impressive the result can become.

Since an embossing cliche is needed for the production, the size of the area to be embossed (# × # cm square) is necessary for the accurate calculation.

Hot foil stamping

Hot foil stamping

During the process of hot foil stamping, a metalized or coloured foil is pressed down on the printing surface with the help of a metal cliche, whose pressure and heat cause the foil to become detached and adhered to the paper.

The result of the process is a highly glossy surface, with genuine metallic shine. The pattern of the hot foil stamping can vary which allows you to design the stamped artwork so that it suits your product the most, making it even more unique.

Since a hot foil stamping cliche is needed for the production, the size of the area to be stamped (# × # cm square) is necessary for the accurate calculation.

Spot UV varnish

Spot UV varnish

Highlighting certain design elements on the packaging with spot varnish can lend a unique appearance to the product. The height of the varnish can be adjusted from 7-micron (i.e. completely flat) to 232-micron thickness. Having a single colour background under the varnish offers a nice and refined look, but the technique can also be used to accentuate specific elements of the artwork.

Metalized foil

Metalized foil

When used on packaging materials, beyond durability and protecting the printing, this surface treatment offers a novel and exclusive appearance. Its usage is recommended if you would like to achieve a genuine metallic effect on the artwork design, in cases when it is important that the product has a prominent look, or if you would like to highlight texts or larger parts of the background with silver or gold colour.

MGI 3D spot UV varnish + digital hot foil stamping

MGI 3D spot UV varnish + digital hot foil stamping

This solution offers a glossy and embossed gold or silver effect on the packaging. During the process, a silver of gold foil is placed on the 3D UV varnish, resulting in the appearance of the traditional hot foil stamping and embossing.

The foil can be used on thin lines or larger, continuous areas of the artwork, alike, without the need of a hot foil stamping cliche, which can generate a considerable cost saving, particularly in case of larger surfaces.

With the combined use of 3D UV varnish and digital hot foil, the end result is a slightly embossed surface, as the minimum height of the varnish is 29 micron. It can be adjusted though under the foil, as well, meaning that the combined effect of embossing and hot foil stamping is also feasible with this technique, achieving the same glossy and shiny effect, as with the traditional hot foil stamping.

Soft Touch lamination

Soft Touch lamination

The Soft-Touch foil offers a matt effect with velvety character. The result is truly impressive when combined with glossy spot UV varnish.